WEC Laser has become one of the largest laser profiling companies in the UK. Comprising of over 900 onsite staff working in our laser, fabrication and machining divisions, we're able to provide a friendly and efficient service whilst acting as a genuine one-stop-shop for our customers.

Why choose WEC Laser?

Continuous Investment

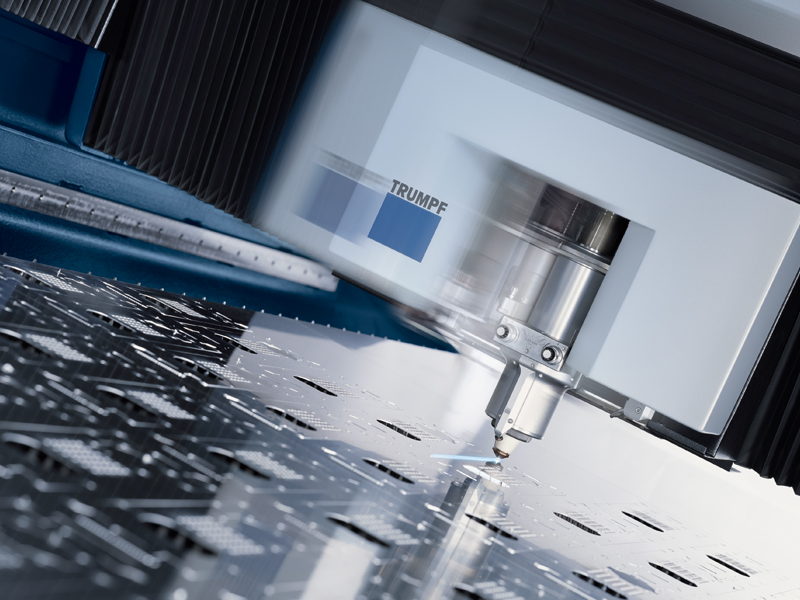

Continuous investment in the latest laser cutting technology is the key to the division's growth over the past two years. Our state-of-the-art CNC laser machines enable WEC Laser to compete at the highest level.

Laser cutting is one of the most popular profiling technologies as it has the ability to accurately cut, melt, burn, or vaporise a range of materials, from Stainless Steel to Aluminium and Brass.

Why use Laser Profiling?

Due to the accuracy of laser cutting, it’s possible to cut small diameter holes with complex detail and good edge quality in either sheet, plate, tube or box section. Not only is it more precise than traditional cutting methods, but it also reduces manufacturing costs eliminating the need for machining on many engineering jobs. For more benefits, visit our laser cutting benefits page.