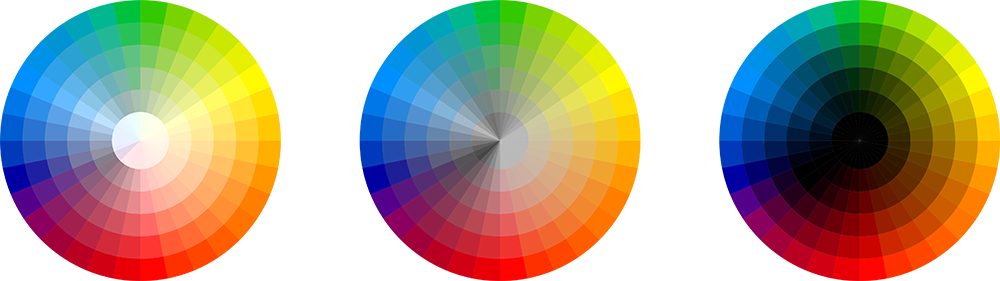

Our specialist in-house powder coating division can handle parts of up to 1.5m x 3m x 800mm in any RAL colour. We can provide high-quality finishing services, allowing us to offer a complete supply solution for laser-cut, folded, welded, and powder-coated assemblies.

Our Capabilities

With significant investments in our cutting-edge fully automated powder coating plant, we can coat components up to 1.5m high x 3m long x 800mm wide. The latest automation technology makes us highly competitive for volume orders and large batches and we can offer short leadtimes.

Our facility features two automatic reciprocators, a 90% powder recovery system, and a 4-stage in-line pre-treatment plant, ensuring cost-effectiveness and environmental friendliness.

Located at our headquarters in Blackburn with Darwen, Lancashire, we offer industrial subcontract powder coating services to various industries nationwide, including retail, rail, street furniture, automotive, and aerospace.

We use a variety of powders, such as Epoxy, Polyester, and Polyurethane, as well as architectural and custom-made powders.