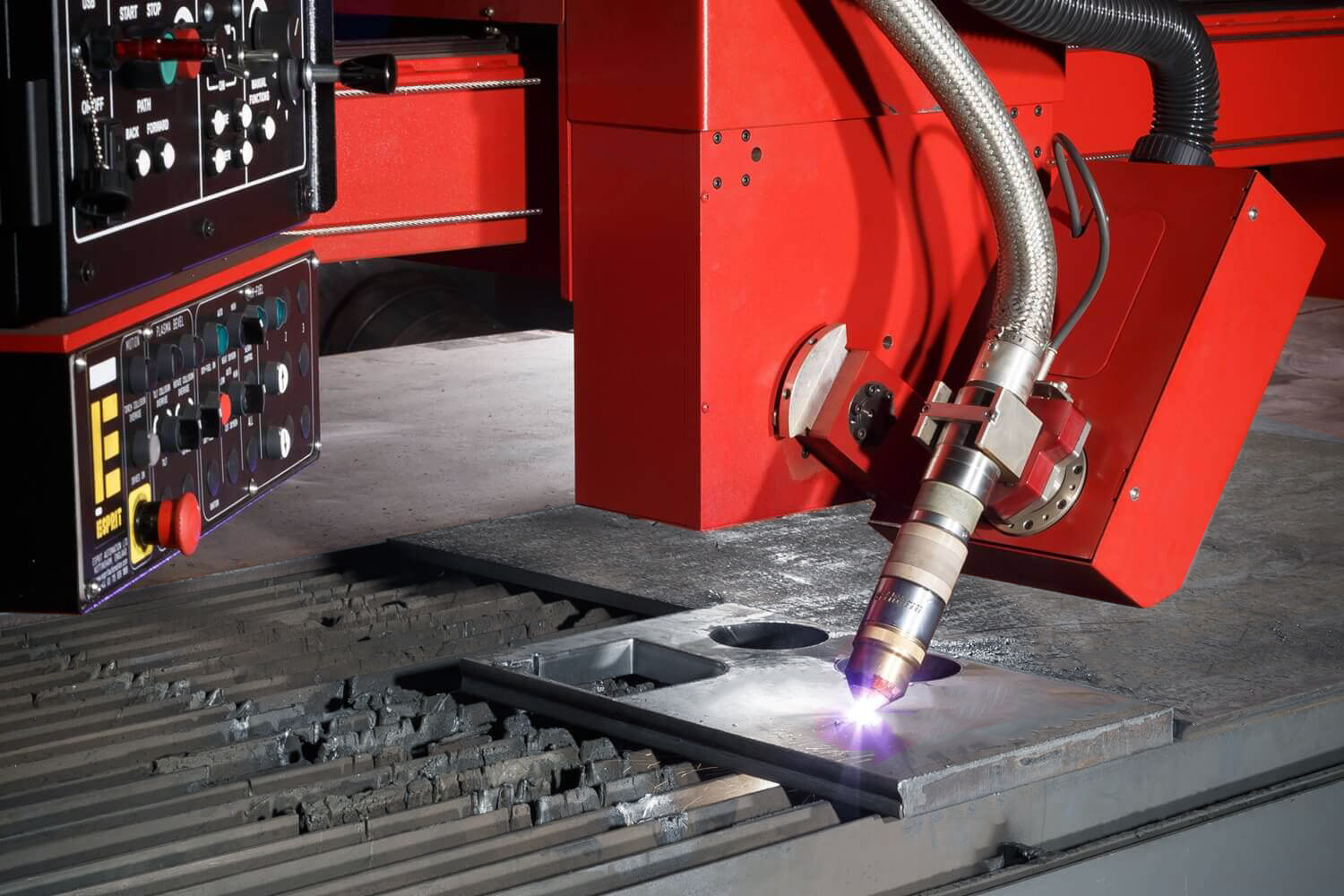

High definition plasma cutting is an efficient profiling method for stainless steel, mild/carbon steels and aluminium components. Utilising the very latest Multi Bevel High Definition Plasma Cutting technology, our plasma cutting division can cut profiles of up to 10m x 2.5m x 50mm thick with a ± 50° bevel cutting capability for weld preps.

WEC Plasma has been set up to add value to our fabrication operations and also improve our subcontract cutting capacity for thick profiles.